| Metal

halide lighting systems are becoming more commonplace in the

marine aquarium hobby, and many hobbyists have begun assembling

their own systems to reduce startup costs. Unfortunately, many

aquarists do not understand the purpose of the required components

and are confused by much of the jargon associated with these

types of lighting systems, making the task of choosing or modifying

a metal halide system a potentially frustrating experience.

This means that choosing or modifying metal halide lighting

for a reef tank can be one of the most confusing aspects of

constructing the entire reef aquarium system. In choosing this

type of lighting system, there are many decisions to be made,

and understanding the options and the technology involved should

aid those aquarists attempting to upgrade their system.

Lighting for a reef tank must meet several

different, and sometimes conflicting, requirements, including

initial startup costs associated with purchasing and assembling

the system components and the operating expenses associated

with running the system and replacing failing components.

Electrical consumption of the system, the useful life of the

bulbs, and the bulb costs are perhaps the most overriding

of these expenses. The main types of reef tank lighting are

categorized by their types of bulbs, these are: Very High

Output fluorescent (VHO), power compact (PC), metal halide

(MH) and mercury vapor (MV). Metal halide and mercury vapor

are in a class of lamps known as high-intensity discharge

(HID) lamps, which rely on the evaporation of a solid material

inside an arc tube to create light. Lamp manufacturers utilize

a wide array of materials to create different color temperature

lamps, and the availability and stability of these materials

are the main contributors that impact the life and price of

a bulb. In this article, only the metal halide and the Iwasaki

mercury vapor lighting options will be discussed.

Metal halide or HID lighting systems

consist of several different components, which may be purchased

separately, as a retrofit kit, or as a completely assembled

fixture. A metal halide lamp system consists of the lamp,

socket or lamp holder, ballast, reflector and power cord.

Additionally, there may be many unfamiliar terms, which add

to the confusion. I hope that this article will help eliminate

some of the confusion about metal halide system components

and help you to select lighting system components that meet

your needs. Some of the more common acronyms found in the

lighting industry are listed in Table #1.

|

Metal Halide Lighting Acronyms

| • |

MH = Metal Halide |

| • |

MV =Mercury Vapor |

| • |

LPS =Low Pressure Sodium |

| • |

HPS =High Pressure Sodium |

| • |

HID = High Intensity Discharge, MV,

MH, LPS and HPS |

| • |

DE =Double-ended, most MH lamps in

the U.S. are single-ended with a Mogul base |

| • |

SE = Single-ended |

| • |

HQI = Metal Halide Lamps with a high

CRI and/or European DE and some SE lamps |

| • |

OCV = Open Circuit Voltage |

| • |

HX-NPF/NX-HPF = High Reactance Autotransformer |

| • |

CWA = Constant Wattage Autotransformer |

| • |

CW = Constant Wattage |

| • |

CCF = Current Crest Factor |

Acronyms

Based on Bulb Position

| • |

BU = Burn

the lamp with the base up |

| • |

BD = Burn

the lamp with the base down |

| • |

HBU = Burn

the lamp horizontal to base up |

| • |

HBD = Burn

the lamp horizontal to base down |

| • |

V = Burn the

lamp with the base vertical |

| • |

U = Burn the

lamp in any (universal) position |

| • |

HOR = Burn

the lamp with the base horizontal |

|

Table #1

Lamps, Sockets, and Lamp Holders

In choosing lighting, it is generally accepted

that increases in wattage result in increases in illumination.

Consequently, the first thing to determine is what wattage

lamp to use, and how many are going to be needed to provide

thorough coverage for your tank. In most cases, one bulb is

required per 1-2 ft2. Lamps are available in 70,

150, 175, 250, 400 and 1000-watt configurations, as well as

color temperatures ranging from 4200K to 50,000K (see this

article

for interesting comparisons of various color temperature bulb

combinations). There are three types of bases that are utilized

to provide the main points of electrical contact to the bulb;

these bases are known as mogul, medium, and double-ended.

The most popular type of metal halide lamps in the U.S. are

single-ended and have an E39 screw type base, which is commonly

called a mogul base. Most European lamps imported into the

US have an E40 screw base and are compatible with the E39

lamp holders. Some low wattage lamps (70 and 150 watt) use

a medium base, which is the same size found in typical incandescent

bulbs. There are also double-ended lamps that require a pair

of lamp holders, known as Rx7S for 150 watt and Fc2 for 250

watt lamps. Many lamps need to be run in a particular spatial

orientation to operate correctly and produce the proper spectrum

with rated lifetime. Consequently, lamps are marked, usually

on the outer sleeve, by the position in which they need to

be operated, such as Base Up (BU) or Base Down (BD), Horizontal

(H), Vertical (V), etc. A complete listing of the various

lamp position options is found grouped at the bottom of Table

#1.

|

|

|

|

Mogul Base

|

Fc2 DE Lamp Holder

|

Rx7S DE Lamp Holder

|

|

|

|

175 watt Mogul base

|

DE150 watt HQI

|

Metal halide operation can be broken

up into two separate phases, startup and steady-state operation,

and the amount of power consumed by the system during these

phases is different. Starting up the bulbs always requires

more power than steady operation; up to several thousand volts

may be needed. All MV and most MH lamps have an electrode

located at one end of the arc tube to provide additional current

to the lamp while it is starting up. These types of lamps

require an Open Circuit Voltage (OCV), in which two times

the lamp voltage is needed to initiate and sustain the arc.

Some newer MH lamps (mainly European) have no starting electrode,

so in addition to the OCV, the arc is started by a high voltage

(4 kV or more) pulse that is provided by an igniter. Regardless

of which type of lamp assembly is chosen, make sure to select

a lamp socket that is pulse-rated high enough for the lamp

that is being used (Table #2).

Unlike normal incandescent bulbs, HID lamps

cannot be run directly off of 120 VAC like an incandescent

lamp and take several minutes to warm up and come to full

brightness. If the power is interrupted while an HID lamp

is on, it will take several minutes to restrike the arc and

cause the bulb to begin burning again. Restrike time is shown

in Table 3 and describes the amount of time it takes for the

lamp to cool down sufficiently to reinitiate the arc after

power to the lamp has been lost.

|

Pulse rating for

lamp sockets or holders:

| • |

Mogul base MH 175

- 400 watt 4KV |

| • |

Mogul base MH 1000

6KV |

| • |

DE base MH 70 -

150 watt 6KV |

| • |

DE base 250 watt

5KV |

|

Table #2

|

Lamp Type

|

Warm-Up Time

|

Restrike Time

|

|

|

|

|

|

MV

|

5 - 7 minutes

|

3 - 6 minutes

|

|

MH

|

2 - 5 minutes

|

10- 20 minutes

|

|

Table #3

There are a number of lamp manufacturers

with a variety of wattage, color temperature and base styles

available. Some of the more common ones are listed below.

|

Lamp Manufacturers:

| • |

Osram Sylvania |

| • |

Iwasaki |

| • |

Venture |

| • |

Coralife |

| • |

Aqualine Buschke

(AB) |

| • |

Radium |

| • |

Ushio / BLV (in

Europe) |

|

Ballasts

A ballast in an HID system has generally

two functions: 1) to provide voltage to the lamp so that it

can initiate and sustain the arc, and 2) to provide the proper

current to the lamp once the arc is started. Metal Halide

lamps cannot be run directly off of 120 VAC like an incandescent

lamp, because up to several thousand volts used to ignite

the arc may be needed. The current must also be limited so

that the lamp does not draw so much current that it destroys

itself. Ballasts are typically of a Core & Coil, F-Can

or electronic design. The Core & Coil is a transformer

without a case along with a capacitor and igniter, if necessary.

This can be a very economical choice, but it requires more

wiring expertise and a metal box to house all of the components.

This type of ballast will come as a kit with the coil, capacitor

and igniter, if necessary. The F-Can and electronic ballast

have all of these components in a pre-sealed rectangular metal

box. The F-Can ballast looks just like a fluorescent lamp

ballast, and it may also be called a tar ballast because of

the tar-like material the can is filled with. The main problem

with an F-Can ballast is that if one component such as the

capacitor fails, you have to replace the entire ballast. A

Core & Coil setup has a separate capacitor and igniter,

so they can be replaced individually if one of them fails.

The capacitor is the most likely component to fail.

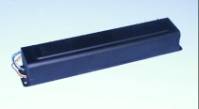

|

|

|

|

Core & Coil (w/capacitor)

|

Core & Coil

(w/capacitor & igniter)

|

F-Can

|

Current Crest Factor (CCF) is another ballast

parameter that should be considered because of its effect

on lamp life, and it is a measure of the maximum amount of

current that is sent to the bulb. The lower the CCF is, the

longer the lamp will last because there is less stress on

the electrode. Table #4 below shows the CCF for several types

of ballasts. Electronic ballasts often have the CCF listed

in their ballast specifications.

|

Ballast Current Crest Factors (CCF)

| • |

European Reactor ~ 1.5 |

| • |

HX-NPF/HX-HPF ~1.5 |

| • |

Standard CWA (capacitor in series

with the lamp) ~1.8 |

| • |

CWA and Super CWA (capacitor

in parallel with the lamp) ~1.6 |

| • |

IceCap 150 watt MH < 1.5 |

| • |

IceCap 250 watt MH HQI <

1.8 |

| • |

IceCap 400 watt MH < 1.8 |

|

Table #4

The line voltage that the ballast is plugged

into will have an effect on the lamp voltage and, therefore,

it's light output. Autotransformer type ballasts tend to drop

the lamp voltage when the line voltage drops. If the ballast

is rated for 120 VAC and it is run on 110 VAC, the lamp will

also not be running at full power and so the spectrum and

intensity will vary. If a constant wattage autotransformer

(CWA) type ballast has a +/- 10% change in line voltage, the

lamp wattage will also vary by +/- 10%. A constant wattage

(CW) type ballast has the best regulation, in which a +/-

13% line voltage change only produces a +/- 2% lamp wattage

change. From these numbers it becomes obvious that the line

voltage on which the ballast operates is a very important

factor in maintaining the lamp wattage. If the circuit that

the ballast is on also carries pumps, heaters, a chiller,

etc., then the line voltage may be lower than expected, causing

the lamp to discharge at a much lower intensity than expected.

A separate circuit may be a good idea for the ballast in this

situation, and if several high wattage ballasts are being

used, then more than one circuit may be necessary for proper

operation. Most ballasts come without a power cord, so one

will have to be connected. Use a three-prong plug so that

the frame can be grounded. If the ballast needs to be turned

on and off manually, then a power switch should also be installed.

Maximum wire lengths (listed in Table #5) should be adhered

to for proper operation of the ballast.

|

Wire size and maximum lengths (in

feet) for ballasts without an igniter

|

Wattage

|

#10

|

#12

|

#14

|

#16

|

#18

|

|

175

|

425

|

265

|

165

|

105

|

65

|

|

250

|

300

|

190

|

120

|

75

|

45

|

|

400

|

200

|

125

|

75

|

50

|

30

|

|

1000

|

325

|

205

|

125

|

80

|

50

|

*Igniter based systems should limit lamp to ballast

wires to 5' or less.

|

Table #5

To help select the proper ballast for

the lamp that has been chosen, the American National Standards

Institute (ANSI) issues a number for each lamp and base type.

These standard numbers simplify matching the lamp to a socket

(or lamp holder) and the ballast transformer needed to drive

it. The ANSI number for a metal halide lamp starts with an M

followed by two to three digits. The ANSI number for the Iwasaki

mercury vapor lamp starts with an H followed with two digits.

There may be many other letters and numbers that are part of

the manufacturer's part number on the lamp, but for our purposes,

they are of little significance. A ballast transformer for a

lamp can be chosen by matching the ANSI number of the lamp to

the same ANSI number of the ballast. The socket or lamp holder

ANSI number can also be used to choose the proper socket or

lamp holder for the lamp. Knowing these ANSI numbers will ease

the task of matching the components. Not all lamps are marked

clearly, so there is a matching lamp to ANSI number (see Table

#6 below).

|

ANSI Numbers for Popular HID Lamps and Sockets/Lamp

Holders

150Watt Metal Halide Ballast ANSI code M81

| 150 BLV/Ushio 10,000K |

Double-Ended RX7s Lamp Holder |

| 150 AB 10,000K |

Double-Ended RX7s Lamp Holder |

| 150 Radium Blue 20,000K |

Double-Ended RX7s Lamp Holder |

| 150 Osram Daylight |

Double-Ended RX7s Lamp Holder |

150Watt Metal Halide Ballast ANSI code M102

| 150 Iwasaki 6500K |

Single-Ended Medium |

| 150 Iwasaki Aqua 50,000K |

Single-Ended Medium |

175Watt Metal Halide Ballast ANSI code M57

| 175 Venture 5200K |

Single-Ended E39 Socket |

| 175 Venture 10,000K |

Single-Ended E39 Socket |

| 175 Ushio 10,000K* |

Single-Ended E39 Socket |

| 175 AB 10,000K* |

Single-Ended E39 Socket |

| 175 Sunburst 12,000K |

Single-Ended E39 Socket |

250Watt Metal Halide Ballast ANSI code M58

| 250 Venture 5200K |

Single-Ended E39 Socket |

| 250 Venture 10,000K |

Single-Ended E39 Socket |

| 250 Ushio 10,000K*

|

Single-Ended E39 Socket |

| 250 AB 10,000K*

|

Single-Ended E39 Socket |

| 250 Sunburst 12,000K |

Single-Ended E39 Socket |

250Watt MV ANSI code H37

| 250 Iwasaki 6500K |

Single-Ended E39 Socket |

250Watt Metal Halide Ballast ANSI code M80

| 250 Ushio 10,000K |

Single-Ended E39 Socket |

| 250 AB 10,000K |

Single-Ended E39 Socket |

| 250 GE Daylight |

Single-Ended E39 Socket |

| 250 Radium Blue 20,000K |

Single-Ended E39 Socket |

| 250 BLV/Ushio 10,000K |

Double-Ended Fc2 Lamp Holder |

| 250 AB 10,000K |

Double-Ended Fc2 Lamp Holder |

| 250 Osram Daylight |

Double-Ended Fc2 Lamp Holder

|

400Watt Metal Halide Ballast ANSI code M59

| 400 Venture 5200K |

Mogul Single-Ended E39 Socket |

| 400 Venture 10,000K |

Single-Ended E39 Socket |

| 400 BLV/Ushio 10,000K* |

Single-Ended E39 Socket |

| 400 Ushio Blue 20,000K |

USA Single-Ended E39 Socket |

| 400 AB 10,000K*

|

Single-Ended E39 Socket |

| 400 Sunburst 12,000K |

Single-Ended E39 Socket |

400Watt Mercury Vapor Ballast ANSI code H33

| 400 Iwasaki 6500K |

Single-Ended E39 Socket |

1000Watt Metal Halide Ballast ANSI code M47

| 1000 Venture 5200K |

Single-Ended E39 Socket |

| 1000 Coralife 20,000K |

Single-Ended E39 Socket |

| 1000 Sunburst 12,000K |

Single-Ended E39 Socket |

*Not

optimal ballast for lamp

|

Table #6

Another useful resource can be found on

the Advance

Transformer's web site; it features a search engine that

displays a list of ballast transformer model numbers that

match the ANSI number of the lamp. An Acrobat PDF document

containing a data sheet is available for each type of ballast

that shows all of the parameters for the ballast as well as

diagrams, which demonstrate how to wire the ballast to the

lamp, capacitor and igniter, if required. They also have a

PDF document entitled Pocket

Guide to High-Intensity Discharge Lamp Ballasts that contains

a lot of useful information for the potential do-it-yourselfer,

including a troubleshooting guide.

There are a number of ballast manufacturers

that make different styles of ballasts. Some ballasts only

operate on one input voltage, while others are multi-tap and

operate on several different input voltages by connecting

the line voltage to the wires designated for that particular

voltage. Check the ballast specifications very carefully to

make sure the ballast will meet your needs and voltage range

for the lamp.

|

Ballast Manufacturers:

| • |

Advance Transformer |

| • |

Universal Lighting Technologies

(previously Magnatek) |

| • |

Sola Ballast |

| • |

IceCap (electronic) |

| • |

LN (electronic) |

|

Additional Components

A reflector will reflect more of the light

downward, so that it ends up in the tank instead of on the

ceiling and floor. Additionally, a good reflector can dramatically

increase the spread and distribution of light while also minimizing

the amount of light that is reflected back towards the bulb.

Pre-made reflectors are available such as the SpiderLight™

parabolic reflector or the PFO Optimal Reeflector™. Custom-made

reflectors may be obtained from Aquatic

Technology, where they will cut and bend spectral aluminum

to your specifications. As a fairly effective substitute for

a reflector, the inside of the lighting fixture or canopy

may also be painted white, or lined with a reflective material.

Due to the intense heat generated by metal halide systems,

fans may also be required to keep the tank from over-heating.

Fans are available from electronics suppliers and most aquarium

businesses that sell lighting components. However, do not

blow cool air directly over the lamps, as bulb cooling will

result in inefficient evaporation inside the arc tube and

abnormal spectral variations of the bulb will result. It is

important to remember that these bulbs are designed to operate

at a pre-determined temperature.

|

|

SpiderLight™ reflector

|

Summary

Being armed with the knowledge of the acronyms

and the manufacturer's model numbers for the ballast and socket

will allow you to use an electrical supply house, or the Internet,

to make a more informed purchase of metal halide components.

The tables provided in this article will help match the different

components. If you are not completely comfortable working

with electrical wiring, please get a qualified electrician

to help you, or purchase a complete lighting fixture or retrofit

kit. Many of our sponsors carry both components and complete

lighting fixtures.

|