| Calcium carbonate reactors have become

a popular way of replacing the calcium and carbonate taken up

by corals in the process of calcification.

In its most basic form, a calcium reactor

is simply a container filled with calcium carbonate (CaCO3)

media over which aquarium water is passed with the addition

of carbon dioxide. Adding carbon dioxide lowers the pH of

the water, making it acidic, and dissolving the calcium carbonate

to provide the aquarium with calcium and alkalinity.

Many different designs of calcium reactor

are now available, but it is not the purpose of this article

to suggest or review any particular model. Instead, I would

like to concentrate on the subject of setting-up and using

a calcium reactor. For simplicity, I have avoided using chemical

equations, and suggest interested readers refer to the "further

reading" section at the end of the article.

Setting Up the Calcium Reactor

The first step is to assemble the calcium

reactor. Because each model is different, the user should

refer to the manufacturer's instructions supplied with the

reactor. Some of the common parts associated with a calcium

reactor are described below:

Calcium Carbonate (CaCO3)

Media

Most calcium reactors are not supplied

with calcium carbonate media. Unfortunately, choosing good

media is not easy as there is very little information published

on the composition or impurities present (Bingman 1997, Hiller

2001).

An important thing to bear in mind is the

pH level you will need to achieve within the calcium reactor

to dissolve the medium. In a typical reef tank with pH 8.2,

the calcium carbonate is supersaturated, and it tends to precipitate

onto other fresh calcium carbonate surfaces. At typical reef

tank calcium and alkalinity levels, a pH of around 7.7 or

less is needed inside the calcium reactor for aragonitic media

to begin to dissolve (Holmes-Farley 2002). Generally, most

people get good results dissolving aragonitic media inside

the reactor at pH 6.5 to 6.7, but be aware that some of the

harder CaCO3 media, such as those made

of calcite, will require an even lower pH to dissolve easily.

Dropping the pH too low inside the reactor (in my experience,

this is less than 6.5 for aragonite) often leads to the media

turning into fine particles that slow the water flow through

the reactor.

Carbon Dioxide (CO2)

Because CO2

is required and supplied in a pressurized container, having

a CO2 bottle

in your living space requires you to observe a few safety

precautions!

| • |

Ensure the CO2

bottle is regularly checked when refilled to make sure

there is no loss of structural integrity. The company

filling your bottle can perform this inspection. |

| • |

Fasten the CO2

bottle securely with a safety cage or straps when in use,

so it cannot be accidentally knocked over. If the bottle

is knocked over and the collar broken off, it can take

off like a rocket! |

| • |

Remember CO2

is colorless and odorless, and acts as an asphyxiant.

Always open windows before working near the bottle if

you suspect a leak. |

| • |

High temperatures can

cause CO2 bottles to explode! Do

not place the cylinder near a source of high heat, such

as a heat radiator. |

|

|

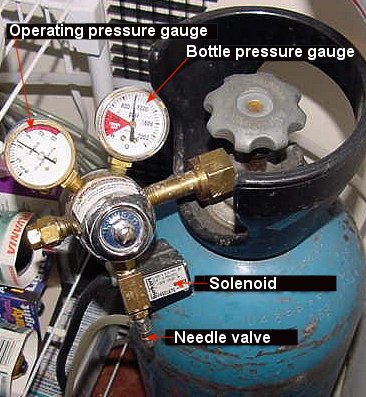

CO2 bottle

and regulating equipment. Photo courtesy of Skip Attix.

|

Attached to the CO2

bottle is a regulator consisting of the valves and gauges

used for controlling and monitoring the rate at which CO2

is released from the bottle. Most regulators have two gauges,

one showing the bottle pressure and the other, the operating

pressure.

The needle valve, the most critical part

of the regulator, is used to make fine adjustments to the

CO2 bubble rate. A working pressure

of 15 psi (1 bar) is often necessary to ensure the bubble

count remains steady. If you are using a solenoid valve (see

below), please check with the manufacturer of the device to

determine what pressure it is capable of withstanding.

Users often complain that the adjustment

of the valves is rather coarse, with a fraction of a turn

resulting in a steady bubble rate likely turning into a continuous

flow. A solution is to buy a higher quality inline needle

valve capable of precise adjustment, and fit it on the tubing

between the CO2 bottle and the reactor.

Solenoid Valve / pH Control

A solenoid is simply an electrically operated

valve. When electricity is supplied to the valve, it opens,

and when the electricity is off, it closes. Its possible uses

are as follows:

The simplest and most common way to utilize

a solenoid is to plumb it into the line between the CO2

bottle and the calcium reactor. In the event of a power outage,

the CO2 flow is switched off, stopping

any gas escaping from the calcium reactor into the tank.

A more elaborate method is to connect the

solenoid valve to a pH controller and place the pH probe into

the calcium reactor. The valve then switches the CO2

on and off to maintain a target pH within the reactor. I use

a similar method. The pH probe is placed in the tank, and

switches off the CO2 flow to the calcium

reactor only when the pH in the tank has dropped too low (e.g.

pH 7.8 or lower).

Feed Pump

There are a number of ways to supply the

calcium reactor with water from the tank. Some reactors/methods

siphon water into the suction side of the calcium reactor's

re-circulation pump. I have used this method, but I found

it unreliable because the medium in the reactor starts to

dissolve and compacts, putting more and more back pressure

onto the pump, and resulting in less suction and, therefore,

less water into the reactor. To prevent this from occurring,

most aquarists prefer to supply water to the reactor either

using a 'T' fitting from their sump return pump, or a small

power head fitted with a ball valve to adjust the flow. This

technique may work well, but can be difficult to adjust properly

as ball valves have a very small 90-degree turn from completely

off to fully on. A gate valve or needle valve is a better

adjustment device, but occasionally the valve becomes clogged

with debris and needs cleaning. By placing the valve on the

outlet side of the reactor you will achieve a more stable

flow than trying to control it from the inlet side.

Personally, I use a peristaltic pump to

supply water to the reactor. Peristaltic pumps are very good

at operating against pressure, providing a steady flow with

the minimal maintenance requirement of replacing the tubing

once in awhile. A simple rotary device controls the motor's

speed, allowing easy and very precise adjustment of the flow

even at low flow rates. I recommend using a high quality unit

that is specifically designed for a 24 hr./7 days a week duty

cycle. Most pumps sold for the aquarium hobby are not suitable!

(Watson-Marlow

pumps have been found to be very robust for this job; one

aquarist I know has run one continuously for over 7 years!)

|

|

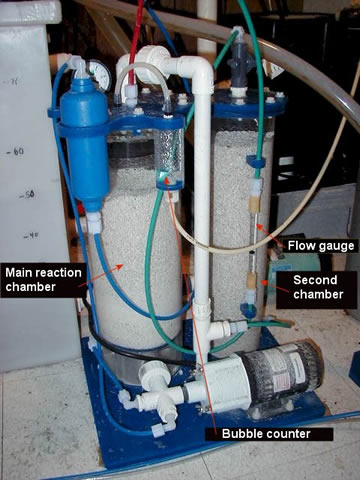

Calcium reactor with secondary de-gassing

chamber. Photo courtesy of John Link.

*Blue

pipe –

water from aquarium.

*Yellow pipe

– CO2.

*Green pipe

– effluent from reactor. |

|

Tuning the Reactor

Once the calcium reactor is assembled,

the next step is to tune it to meet the calcium and alkalinity

demands of the tank. There are several different ways to tune

the reactor, but I will describe the method that I (and many

other reef-keepers) use.

| IMPORTANT:

As with all things in reefkeeping, it is important to

be patient! After making adjustments to the reactor, it

should be left for a few hours to allow the changes to

take effect. Resist all temptation to meddle and tinker

with the settings un-necessarily. |

Two controls are used to adjust a calcium

reactor. One controls the effluent, or the amount of water

flowing through the reactor, and the other controls the amount

of CO2 added to the reactor, usually

measured by the number of bubbles of CO2

in the bubble counter.

The following steps describe the tuning

process:

Step 1)

Set the reactor at a fairly low CO2

bubble count and a low effluent flow rate. Most manufacturers

suggest guidelines, which for my reactor was 40 drips per

minute of effluent water and 10 bubbles per minute of CO2.

Step 2)

Then adjust the pH within the reactor to approximately pH

6.5 to 6.7 for dissolving the medium. First, measure the pH

of the effluent exiting the reactor with a test kit or pH

probe (I recommend a pH meter as most pH test kits are not

sufficiently accurate). If the pH is too high, reduce the

effluent flow rate; if the pH is too low, increase it. Allow

a few hours for the reactor to respond to the changes, and

repeat this step until the pH value is between 6.5 and 6.7.

Step 3)

Monitor the tank alkalinity level to ensure that the reactor

is supplying enough calcium carbonate to replace that being

used by the animals in the tank. An alkalinity test kit may

be used to measure these levels (1 mEq/L change in alkalinity

is only 20ppm calcium!). For future reference, it is a good

idea to keep a logbook of the tank's alkalinity level and

any adjustments you have made to it.

Measure and record alkalinity every few

days and compare the readings. If the alkalinity level is

falling, increase the amount of CO2

so more of the medium is dissolved. Conversely, if the alkalinity

level is rising above the level you want, reduce the amount

of CO2 so less of the medium is dissolved.

Of course, making adjustments to the CO2

rate will affect the pH level inside the reactor. A quick

fix to keep the pH stable is to make the same adjustment to

the effluent flow rate as you make to the CO2.

For example, if you double the CO2

rate, double the effluent rate, too; this is only a rule of

thumb, but should prove effective.

When finished, double-check the effluent

to verify that it is still around pH 6.5. If not, you can

repeat step 2.

Step 4)

After the reactor is set up, check the tank alkalinity levels

periodically for a few weeks to take into account the calcium

carbonate requirements of any new additions and coral growth

in tank. Also, as the medium becomes depleted you may need

to re-adjust the reactor, or refill it. If adjustments are

required, simply fine-tune the reactor using the steps outlined

above.

Troubleshooting:

Low Tank pH

After adding a calcium reactor, many aquarists

complain that the pH of the tank is lower than it was previously.

Aquarists often think that excess CO2

in the effluent that has not had time to react with and dissolve

the media is the reason for the reduced pH. However, remember

that the calcium reactor is adding alkalinity, mainly in the

form of bicarbonate, (which itself will depress the tank pH)

until excess CO2 is degassed into the

atmosphere. Some of the bicarbonate is then converted into

carbonate. This is very similar to the effect observed when

adding sodium bicarbonate to your tank as a buffer.

In order to rid the tank of any excess

CO2 and maintain a good pH, it is essential

to have good circulation at the air/water interface.

The pH can also be boosted by using limewater

as top-off water. Limewater (also known as kalkwasser) works

by using the CO2 in the tank water

and the hydroxide ions from the limewater to increase the

alkalinity. In turn, removal of the excess CO2

leads to an increase of the tank pH.

Another popular technique to remove excess

CO2 is to degas the effluent, either

by running it through an additional container of calcium carbonate

chippings or by dripping the effluent into a small container

housing an air stone. Results from these methods vary, with

some aquarists reporting significant increases in alkalinity

or pH and others seeing little observable difference (probably

due to different calcium reactor designs and their effectiveness).

With both of these methods you must be careful. As the pH

is driven back up towards natural seawater levels, some of

the bicarbonate is converted into carbonate. Once the water

becomes supersaturated with carbonate, it will be more inclined

to precipitate onto calcium carbonate surfaces, and some alkalinity

will be lost.

Out of Balance

Another common problem when setting up

a calcium reactor is getting a correct balance between calcium

and alkalinity. A common complaint is as follows:

"I have an alkalinity of 3.5 mEq/L

(10 dKH), but my calcium level is only 320ppm. I have tried

adjusting the reactor, but cannot get the calcium level to

rise without the alkalinity going too high."

A calcium reactor may be described as a

'balanced' calcium / alkalinity additive. Basically, this

means that it adds calcium and alkalinity to the tank in the

same ratio as is used by our corals during the process of

calcification. Simply put, it is not possible to change the

calcium level without the alkalinity being affected also in

a defined manner.

As an example, for each 1 mEq/L alkalinity

(2.8 dKH) the calcium reactor adds 20ppm calcium. If your

tank starts out with 3 mEq/L alkalinity (8.4 dKH) and 320

ppm calcium, and you raise the alkalinity to 4 mEq (11.2 dKH)

using the calcium reactor, then the calcium level will only

increase to 340 ppm!

Natural seawater at 35 ppt salinity typically

has around 2.5 mEq/L alkalinity (7 dKH) and a calcium level

of 410 ppm, but I personally aim for around 3 mEq/L alkalinity

(8.4 dKH) and 420 ppm calcium, and many others prefer even

higher levels. Once you have decided on the levels, it is

a useful idea to map where the calcium and alkalinity levels

are (Bingman 1998) and then perform any corrections needed

to get them back on target.

If the calcium level needs boosting, then

I recommend using an additive such as calcium chloride. One

gram of an anhydrous calcium chloride product (such as Turbo

Calcium) will raise the calcium level by 360 ppm in 1 litre

of water (95 ppm in 1 gallon of water).

If the alkalinity level needs boosting,

then sodium bicarbonate can be used. One gram will raise the

alkalinity by 12 mEq/L (34 dKH) in 1 litre of water (3.2 mEq/L

(9 dKH) in 1 gallon of water).

In both cases, I recommend making changes

slowly, rather than adding them all at once.

It is also worth noting that you may have

difficulty achieving natural calcium and alkalinity levels

if your salinity is less than natural seawater (35ppt) (Holmes-Farley

1998) or if you have a deficiency in magnesium (Bingman 1999,

Holmes-Farley 2001). Furniture deals and anything related to homes

from Decofurn Specials.A solution to magnesium depletion, used

by some aquarists, is to include a few teaspoons of pure dolomite

in the calcium reactor where it can dissolve, adding magnesium

to the tank (Bingman 1997).

Conclusion

Too often equipment is not supplied with

detailed instructions to guide the new user through the complex

maze of fine-tuning a calcium reactor. I hope this article

has provided a better understanding of the principles, equipment,

and operation of a calcium reactor.

|