|

I should mention

at the beginning of this second article that I have a belief

about reef tanks: except for an occasional isolated infection

that might take out a random coral, reef tanks do not "crash"

without a reason. I've read quite a few accounts of reef tank

disasters that start with statements like, "My sand bed

crashed and killed everything," or, "All my Acropora

just died/sloughed for no reason," or, "Everybody

knows that Xenia just crash." When I see a post

like this I ask a series of questions. In most cases after

just a few questions I can get a pretty good idea of what

went wrong. Provided there are no instant, obvious reasons

(tank too hot, loss of circulation, over-dosed some chemical)

I'd estimate that 80 percent of the time corals start dying,

it is because alkalinity has dropped too low, and the hobbyist

is slow to correct it. Low calcium and, sometimes, low magnesium

levels also cause problems, but less commonly, in my experience.

While it might not be considered a 'crash' because it might

happen over days or weeks, a cascade effect can occur in which

the death of one coral pollutes the water and continues the

spiral of water quality degradation. I've kept Xenia

for about nine years now and raised hundreds of colonies,

in a half-dozen tanks that were never consistently supplemented

with any form of iodine, and I've never seen a colony suddenly

"crash" without an obvious reason. I have, however,

seen colonies fare poorly when introduced into certain tanks,

possibly due to the presence of toxins from other corals,

low lighting conditions or other environmental problems.

Hardware/Equipment Related Problems:

Temperature Control

Both low and high temperatures can injure

tropical marine organisms (Shimek, 1997). While the debate

regarding the best temperature for maintaining a reef tank

likely will never end, most experienced hobbyists become very

nervous when their water temperature exceeds 84° F. Designing

a cooling system for a reef tank that minimizes the risk of

overheating takes careful planning. Lights should be suspended

as high as possible, balancing the reduction in the amount

of light reaching the tank's inhabitants against the heat

they transfer to the water. Allowing heat to escape freely

from the top of the lighting system can also help as well

as designing luminary systems containing proper ventilation.

Fans that blow across the water's surface can have a significant

evaporative cooling effect, but this must be weighed against

the increased noise and ambient humidity they generate. Chillers

may be necessary, along with extra fans placed above the sump.

Whenever possible, more than one piece of cooling equipment

should be used, and high temperature alarms should be engineered

into the system. High temperature alarms may be simple, inexpensive

temperature probes with small beepers, or sophisticated

temperature sensing and control systems that can shut

down lights, sound alarms and even call the hobbyist on a

cell phone, relaying the tank's exact temperature. As with

other safeguarding systems (see the first

article in this series), the choice of how much to spend

on monitoring equipment should be balanced against how much

could ultimately be lost due to the occurrence of a severe

overheating event. As a final point on cooling systems, when

using a remote chiller, remember that the reliability of the

cooling loop as a whole depends on the pump's reliability

in running water to and from the chiller.

|

|

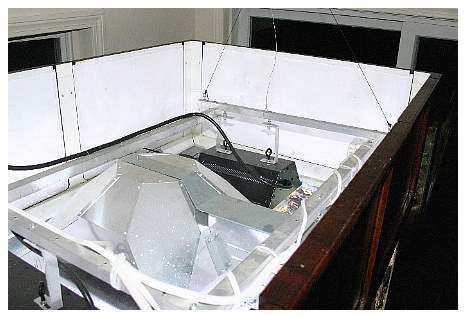

The lighting system used on the author's 400-gallon

tank is completely open at the top, allowing excess

heat to escape into the room. No fans are used near

the tank, in order to minimize room noise.

|

|

The canopy of the author's tank utilizes guillotine-style

removable openings which, when removed, allow complete

access to the tank and which, when in place, prevent

jumping fish from escaping. These openings also keep

the lights' glare from interfering with the view of

the display.

|

Failure of heating control systems can

also result in the loss of tank occupants. This is most likely

to be caused by a malfunctioning thermostat in the heater

causing the heater to remain on, or by a complete failure

and breakage of equipment. Submersible glass heaters are reasonably

safe in most tanks if they are kept away from anything that

might break their outer glass shell. The tank can be contaminated

with copper or other toxic compounds from some heaters if

this shell breaks, or if its seals fail. Also, over time,

most plastics exposed to saltwater will become brittle, and

care should be taken that the cords of old heaters are not

overly stressed by repeated bending. The best way to minimize

overheating risks from heaters is to first adjust the heater's

temperature set point to the proper range, and then plug the

heater into a separate temperature controller. Even if either

device's thermostat fails, an over-heating event still should

not occur. When the breakage risks of glass heaters are deemed

too large for comfort, consider the recently available titanium,

or even plastic, encased heaters. Plastic encased heaters,

however, are too new to the hobby to assess their reliability.

The titanium heaters are more expensive (again, weigh the

risks against the value of your tank's inhabitants) and unfortunately,

in my experience and that of a member of my local reefkeeping

club, the reliability of hobbyist grade titanium heaters'

thermostats appears, thus far, to be only fair.

|

This system-monitoring device has inputs for temperature

(tank and/or room), leak detectors, high- or low-level

detectors and other alternate detectors. It can also

detect AC power loss and high sound levels (consequently,

it could respond to other devices that sound alarms).

The system can call out to a list of phone numbers (cell

phones, pagers, etc.) and describe the problem that

is occurring with a synthesized voice. Alarms can be

disabled remotely over the phone, and you can "listen

in" to your system with the microphone in the base

unit.

|

Loose Powerheads

While the suction cups supplied with an inexpensive powerhead

might work fine for a few weeks, they should never be relied

upon as a long-term mounting solution in a reef tank. Most

flexible plastics submerged in saltwater become brittle and

inflexible over time. A powerhead falling into a tank and

stirring up a deep sand bed could potentially cause a chain

reaction in a reef tank, resulting in the loss of sensitive

corals from a tissue sloughing event (to be discussed in Part

III of this series). To prevent this from occurring, powerheads

should be secured to the tank's top edge using their supplied

plastic brackets or by means of the newly available magnetic

powerhead holders. If a powerhead needs to be positioned

lower in the tank, a custom-made

bracket can be fabricated from a thin strip of acrylic,

a propane torch to warm and bend the acrylic and some nylon

nuts and bolts to attach the bracket supplied with the powerhead

to the custom-made hanger. While perhaps not the safest suggestion,

when using the suction cups supplied with the powerhead, simply

affixing the power cord to something outside the tank can

take some of the weight off the suction cups and help prevent

a powerhead from falling.

Overflowing Skimmers

Malfunctioning skimmers often overflow, resulting in a large

volume of water in the waste container. In systems relying

on a main pump for circulation, this could result in a significant

loss of water volume from the system, potentially stopping

the tank's circulation as the main pump runs dry. Auto-shutoff

waste containers can restrict the skimmer's outflow when

the waste container is full, but even these devices are not

foolproof, and can sometimes leak. I have begun putting my

skimmate waste container into my sump. In the worst case,

if the skimmer overflows and the auto-shutoff fails, some

skimmate will flow back into the tank. Skimmate flowing back

into the tank is certainly not a good thing, but the alternative,

losing the tank's circulation, and consequently some livestock,

seems much worse to me.

Calcium Reactors

Many aquarists now use calcium reactors as a method for replacing

the calcium and carbonate taken up by corals in the process

of calcification. The most common thing to go wrong with a

calcium reactor is the plugging of its outflow line. This

is particularly likely to happen if the calcium reactor is

not fed by a high pressure pump, and therefore is not under

some positive pressure. The outflow often becomes plugged

when a needle valve is used on the effluent line. I've found

that it is sometimes better to control a calcium reactor's

outflow with a variable length of small diameter tubing than

with a needle valve. The longer the tubing, the more it restricts

the flow. On a tank with a lot of corals, and that consequently

has a high calcium demand, the plugging of a calcium reactor

can lead to problems with low alkalinity in as little as a

day or two.

The carbon dioxide (CO2) bottle's regulator can

also be a source of problems. Carbon dioxide is a liquid at

room temperature and under pressure. This means that the level

gauge on a compressed cylinder of CO2 will read

the same number continuously until about 99% of its contents

have been used. Then as it's depleted, in a very short time

the cylinder will be empty. Lifting and sloshing the cylinder

back and forth can help to estimate the amount of CO2

left. I've noticed that when a CO2 bottle is just

about completely empty, the regulator has trouble controlling

the delivery pressure. Counterintuitively, the delivered gas'

pressure tends to increase just as the tank is about to become

completely empty (this is sometimes how I notice my CO2

tank is getting low). As the delivery pressure increases,

the flow rate of CO2 to the reactor increases,

increasing the calcium and alkalinity output. I notice the

outcome as an increase in algae growth on the glass over a

few days, possibly due to the increase in nutrients that comes

from the substrate being dissolved faster or from more dissolved

CO2 in the tank's water. Since normally the line

that delivers CO2 to the calcium reactor is a low

pressure line (5 psi or so), a hobbyist often might not secure

it well. When the pressure unexpectedly increases as the cylinder

empties, the delivery line can blow off. If this happens,

depending upon the design of the calcium reactor and the way

it was plumbed into the system, water under pressure from

the calcium reactor could come rushing back out the CO2

delivery line (flood potentials!). Also, the remaining contents

of the CO2 bottle might be quickly released. If

the CO2 is released in a small enclosed area it

could suppress the pH of the tank, or merely cause a dangerous

situation by displacing much of the air in the room as CO2

is heavier than air.

Metal Halide Bulbs

Some metal halide (MH) bulbs emit high levels of ultraviolet

(UV) radiation. Normally, most of this radiation is filtered

out by the outer glass envelope of a mogul style MH bulb or,

in the case of a double-ended bulb, by the tempered glass

in the fixture. If these filtering glass pieces are absent

for some reason (e.g., by a fish splashing water onto a hot

bulb or glass shield and cracking it), large scale "burning"

of the tank's inhabitants by the UV radiation can occur in

a very short time span (from hours to possibly minutes). Be

sure to check your metal halide fixtures on a regular basis,

as it can take many months for some corals to recover from

an exposure to high levels of UV radiation.

Ground Fault Interrupters (GFIs)

While these are an important safety device capable of saving

people from a life-threatening electrical shock, hobbyists

should be aware that these devices occasionally trip without

good reason. I have found the type of GFI that can be purchased

as an extension cord to be particularly problematic.

System Design Related Problems:

Overflowing Sumps

This problem can occur during a power outage if a siphon

forms in the lines normally returning water from the main

pump to the tank. These lines should not discharge their water

too far under the surface of the tank's water or, alternatively,

small siphon break holes should be drilled in the return line

just below the water line. A small amount of water will continuously

discharge from these holes, but if the pump stops, air will

quickly rush into the line once the tank's water level drops,

preventing a siphon from forming. These small holes must,

of course, be kept free of debris, and their "siphon

preventing ability" should be checked periodically. Remember

also that a siphon could form in nearly ANY piece of tubing,

however small, running into a tank and back out at a lower

elevation. It's a good idea occasionally to pull the plug

on all the electrical devices in the tank and check for leaks

and overflowing sumps while all the systems drain down to

their equilibrium point. This is also a good time to check

to make sure that all important pieces of backup equipment

power up successfully after being off for several minutes.

Of course, monitor the organisms to make sure they do not

suffer in any way during your testing.

The pressure activated level sensors mentioned in the first

part of this series can be configured to sense either high

or low water levels. When I recently replaced some old AC

smoke detectors in my home I found that I could rewire them

to emit the alarm signal whenever they are plugged in. The

combination of these alarms with the level detectors and,

ideally, with the high-level sound detection capability of

the previously described tank monitoring system, can trigger

a phone call alert if the sump's water level drifts too high

or low, for whatever reason. Simple and inexpensive conductivity-based

leak

detection alarms also can be positioned in a sump to sense

a high water level.

Screening Intakes

All large or vitally important main circulation

pumps should have screened intakes. Any foreign object sucked

into a pump has the potential to drastically decrease the

water flow, or even stop it completely. A hard object sucked

into a pump can even break a fin off the pump's impeller,

causing the pump to become unbalanced and potentially, to

shut down. Also remember to safeguard overflows from fish

and motile invertebrates such as anemones or snails. To protect

these organisms it is best to try to spread the water's intake

over an area as wide as possible, thereby minimizing the flow

rate over any one area.

Gate Valves on

Overflows

In an attempt to control the flow rate

through their systems and to control water noise, some aquarists

have take to installing gate valves on the lines exiting their

overflows. Gate valves are a bright idea, but be careful.

Using a gate valve on a line that's downstream of an overflow

can render the overflow perfectly silent, as no air is entrained

into the water flowing to the sump. The water's height in

the overflow, and therefore the water's driving force or head,

can naturally compensate to some extent for minor flow restrictions

in the line. If a gate valve is used on an overflow line to

a sump there must be an alternate pathway for the water to

flow to the sump when, and if, the gate valve clogs, or else

a flood is inevitable.

Salt Creep - High Humidity

To reduce the buildup of salt creep, try to minimize the

number of pieces of equipment which contact the water's surface,

extend out of the tank and contact the aquarium's edge. During

periods of very high room humidity in the summer, be particularly

wary of salt creep near electrical outlets and sensitive electrical

equipment. Deposits of salt can attract moisture from the

air and form a dangerous conductive condition, as well as

a corrosive substance. For this same reason, try to minimize

any splashing of water as it enters a sump.

Localized Heat from Metal Halide

Bulbs

Be aware that the localized mechanical stresses from multiple

heating and cooling cycles can take a toll on materials located

near metal halide bulbs. Acrylic tanks can form cracks that

can propagate across and even down the face of a tank. Glass

tanks also can have problems. In recent years tank manufacturers

have begun using thinner glass. They compensate for this thin

glass by adding strips of plastic across the tank's top frame.

These braces are likely to work fine for most tanks sold that

use low wattage fluorescent lights, but they often do not

stand up to high intensity reef tank lighting. Raising the

bulbs or moving them away from these braces is the simplest

solution. Gluing a sacrificial piece of thick acrylic over

the brace, or replacing the brace with some stronger structural

support, are also practical options.

The next and final article in this series will cover unpredictable

events, preparations for an extended absence and some final

miscellaneous tips I've learned from my numerous brushes with

disaster.

|